How Pharmaceutical Ampoules are Manufactured - A to Z (2022 Updated)

The Indian Healthcare Sector is expanding, which is responsible for generating demand for reliable pharmaceutical instruments and treatment. Similarly, packaging containers Ampoules are glass containers that are used for storing medicines in a hygienic manner.

The medical ampoules containers used by healthcare professionals have revolutionized the industry by developing a safe, hygienic, and effective way to store, transport, and use liquid and powder medicines.

History of Ampoules

Ampoule-like containers have been used to store liquids for hundreds of years. Early martyrs preserved the blood of the dead in ampule-like containers so as to prepare the dead for resurrection.

In 1890, French pharmacist Stanislaus limousine invented the first hermetically sealed glass module. As a solution to the problem of injectable solutions deteriorating or becoming contaminated during transportation, Limousine developed this technology. The glass bottle had a tapered neck like today and was sealed with an open flame after it was filled.

Recent Ampoules

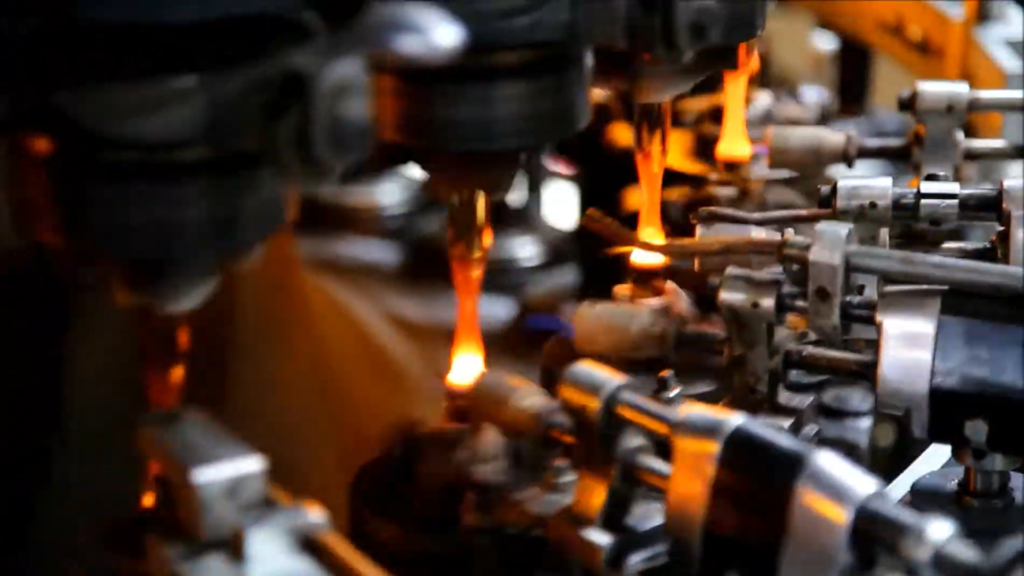

There are many variants of an ampoule currently, but the basic design remains the same. The ampoules are produced by cutting and molding glass tubes using hot flames. These containers are made of plastic or glass, carrying chemicals or biological agents. The basic components include air-sensitive chemicals, injectable solutions, hygroscopic materials, medicines (liquid and powder), and analytical materials.

Glass Ampoules

Glass ampoules are of various types and are the perfect packaging solutions for pharmaceutical and cosmetic products. Amputech Industries, are leading glass ampoule manufacturers in India incorporates its many years of experience in the systematic production of ampoules to guarantee that they are safe to use and always of excellent quality.

Glass Ampoules Manufacturing Process

The production process of ampoules starts by filling carousels with glass tubes, this is the first stage. These glass tubes are made.

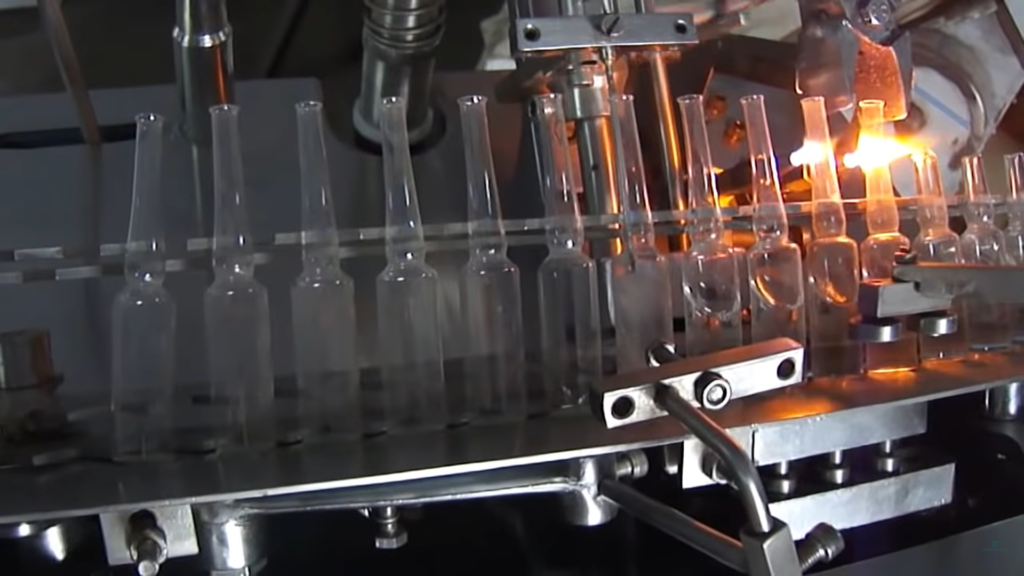

the second stage is shaping, where the ampoule is shaped from the base to the tip, next it is separated from the glass tube. Soon, the ampoule has been separated, the base of the next one is shaped, with the code rings in various colors, and combinations can be applied after.

Similarly, the glass surface between the ampoule body and neck is correctly set, such that when the user presses the ampoule neck at OPC, it breaks at precisely that point.

The purpose to manufactured Glass ampoules is to prevent glass splinters at the breakpoint which could Glass ampoules are manufactured so that no glass splinters are created at the breaking point which could spoil or stain the content.

Considering safety precaution, each product is packed with technical details and use an instruction manual. Finally, the slash or cut are positioned to OPC ampoules, if needed they can be printed as per customer specifications. The next step of the process takes place in the kiln at approximately 600° Celsius when the colors are burned on and the ampoules are tempered.

Amputech Industry glass ampoules manufacturers ensure quality check at all stages of the production process, thus ampoules are inspected at regular intervals by cameras, the human eye, in-process controls (IPC), and in the laboratory.

Ampoules Packed and Delivery

After completion of production, follows dispatch and execution. Glass ampoules are stored in trays, stacked on pallets, sealed in foil, and delivered to customers. During this stage, respective trays are all labeled with customer-specific data, including batch number, production date, and inspection number.

Glass Ampoules for the Health care industry

Glass Ampoules are demanded by healthcare professionals, for packaging ensuring maximum protection for emergency drugs, anesthetics, painkillers, and inflammation inhibitors, also medications and diluents for lyophilized applications. Amputech Industry offers a range of effective storage for non-injectable solutions.

Amputech Industry manufacture glass ampoules in India offers customizable ampoules as per your preferred closure, length, diameter. single Use, etc.

Get in touch with us, if you need more information, glass ampoules samples, or price. Our product expert would be delighted to talk to you.

Rajeev Wadhwa

Email: contact@amputechindustry.com

Phone: +91-9428657179

LinkedIn: LinkedIn