Indian Standard is Identical with ISO 1987–1 : 2000 “ ‘Injection equipment for medical use — Part 1 : Ampoules for injectable’ issued by the International Organization for Standardization ( ISO ) was adopted by the Bureau of Indian Standards on the recommendations of the Medical Instruments and Disposable Sectional Committee and approval of the Chemical Division Council.

1) Dimensions and designation

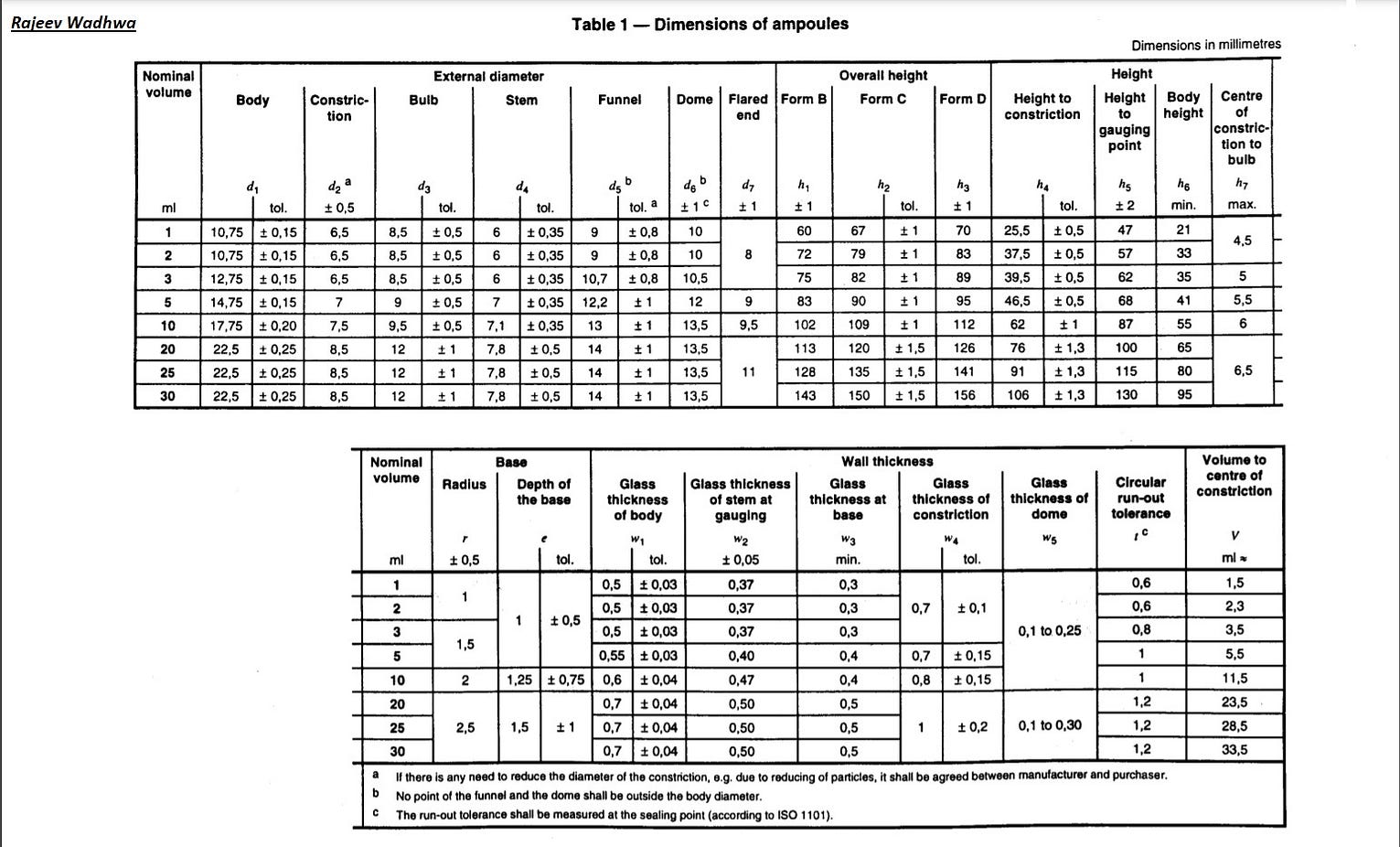

1.1) Dimensions

Form B Ampoules (Stem Cut) are considered well-proven and economical primary packaging for medical Use

Form C Ampoules (Open Funnel)

Form D Ampoules (Closed Ampoules)

1.2) Designation

Designation consist of Descriptor Word “ampoule” + Reference (ISO 9187–1) + Ampoule Form ( “B” “C” “D”) + Nominal Volume ( Size 1 to 30 ml) + Color of Glass (Clear “cl” or Amber “br” + Color Break Ring (cbr) if applicable

Example:

a)Ampoule ISO 9187–1-B-4-br

(4 ml amber glass Form B Ampoule)

Designation of a form B ampoule without a colour break-ring with a nominal volume of 4 ml, made of amber glass (br) complying with the requirements of this part of ISO 9187

b) Ampoule ISO 9187–1- B -10- cl- cbr

Designation of a form B ampoule with a colour break-ring (cbr) with a nominal volume of 10 ml, made of colorless glass (cl) complying with the requirements of this part of ISO 9187

2) Material

Silica (main glass-forming constituents) + Boron Trioxide(main glass-forming constituents) + Other = Borosilicate Glass

Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), making them more resistant to thermal shock than any other common glass.

Colorless (cl) or amber (br) glass of hydrolytic resistance grain class ISO 720 HGA 1 shall be used.

3) Requirements

3.1) Hydrolytic Resistance of Glass : Glass containers are classified according to their resistance to chemical attack, a test executed by heating the glass in contact with water for 30 min at 121 degrees C.

The hydrolytic resistance of the internal surface of ampoules shall comply with the requirements specified for hydrolytic resistance container class ISO 4802- HC 1.

3.2 ) Annealing Quality

During Production of Ampoules — Annealing process takes place in the Furnance at approximately 600° Celsius, when the colours are burned on and the ampoules are annealed. The maximum residual stress of uncolored ampoules after annealing shall not produce an optical retardation exceeding 50 nm per millimetre of glass thickness.

3.3) Breaking force

It is presumed that the ampoules to be tested are provided with a predetermined breaking point, such as a ceramic ring, at the constriction. When tested in accordance with clause 6, the breaking force shall be as specified in Table 2.

4.)Test for Breaking Force

4.1) Principal:

The test is suitable for determining the force required to separate the ampoule stem from the body and for assessing whether a clean break is obtained.

4.2) Apparatus:

Tensile testing machine in accordance with ISO 7500–1 and having the following characteristics:

– test speed, v: 10 mm/min;

– measuring range for force: 200 N

4.3) Condition of Samples:

The temperature of the samples shall be 20 “C ~ 5 ‘C.

5) Delivery

5.1) Ampoules shall be sorted according to their design and nominal volumes, and shall be delivered in packaging units

5.2) Secondary sorting of ampoules according to the stem diameter, da, in the measuring axis, if desired, shall be subject to agreement between the manufacturer and user.

6) Packaging

6.1) The packaging unit shall have the following dimensions:

— length (internal): 384 mm;

— width (internal): 143 mm;

— height: height of the relevant type of ampoule + 2 mm.

NOTE Packaging units with other dimensions as laid down in 8.1 should be agreed between manufacturer and user.

6.2) The immediate packaging of all ampoules shall, as far as possible, be made from materials that do not shed particles

7) Marking

The following information shall be marked on the packaging:

— the manufacturer’s name and address;

— the designation in accordance with 3.2.

Further marking shall be subject to agreement between the manufacturer and the user.

For Ampoule Requirement : Call us at +91-9428657179 & Email us at : contact@amputechindustry.com

Visit : (amputechindustry.com)

Connect on LinkedIn with Rajeev Wadhwa

Rajeev Wadhwa MBA, Symbiosis Institute of Business Management (SIBM , Pune) Batch 2010 (Finance).Working as Marketing Consultant